Other Material

Fiberglass

Fiberglass insulation, which is sometimes referred to as glass wool, is easily the most common insulating material on the market, due in part to its low cost. Fiberglass is made by combining glass (35% or more of which is recycled glass), sand, soda ash, limestone and other minerals.

Mineral Wool

Mineral wool is an insulation material manufactured from natural or synthetic fibers such as slag or ceramics. After heating to a molten form, the fibers are woven together by a process referred to as melt spinning. It is then sold as loose fill or formed into batts or boards for use as insulation.

Cellulose

Cellulose is an inexpensive loose fill insulation, most commonly used as a blow-in material. Cellulose is environmentally friendly as it is manufactured from recycled cardboard, paper and other similar materials.

Polyurethane Foam

Applied with a spray gun, polyurethane foam is excellent for filling around pipes and getting into tiny crevices. Although installation costs are higher than fiberglass or cellulose, polyurethane foam is also one of the most efficient types of insulation.

Expanded Polystyrene (EPS)

Expanded polystyrene (EPS) is a lightweight, rigid, closed-cell insulation material manufactured in many different densities to resist compressive loads. EPS is made from molten polystyrene beads that are formed into blocks or boards. EPS can be cut with a saw and resists water absorption and vapor penetration.

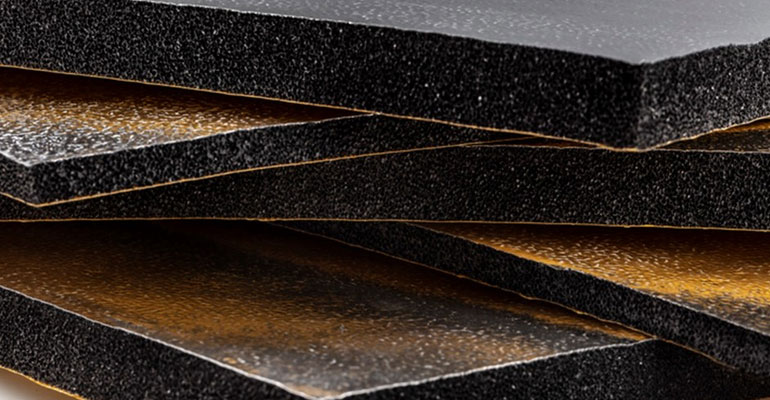

Extruded Polystyrene (XPS)

While extruded polystyrene (XPS) resembles EPS, it is manufactured using a different process. XPS is easily visually distinguished from EPS material by its color. EPS is white, while XPS is blue, green or pink. XPS is recyclable and commonly used in below-grade applications.